Cast-in Pipe Insert Castings Cast-in Pipe Insert Castings |

Cast-in pipe technology is to lay copper or steel pipes inside

castings without pipe damage. These pipes are used for heat control of

molds.

We can set these pipes uniformly along the shaped surface.

Therefore thermal conductivity is high and temperature of molds can be

changed up and down effectively. |

|

|

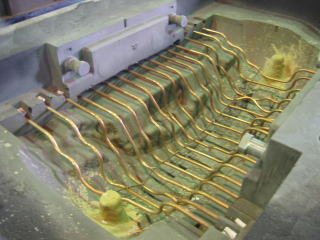

■ Copper Pipes |

| The castings are made of ZAS and have copper pipes inside.

We select copper pipes, for ZAS castings because copper pipes can resist

low melting point of ZAS and copper pipes are easy to curve. The thermal

conductivity is high because we can lay pipes more freely by this method

than by hole drilling device. |

| ■ Effect on Molds |

|

|

| Castings with cast-in copper pipes are effective in molding

with high temperature or with heat control. We can deal with molds of varied

thickness in parts or thin-walled molds. |

|

|

■ Steel Pipes |

The castings are made of FC or FCD and have steel pipes.

Normally steel pipes can not resist melting point of iron.

We developed cast-in pipe technology with steel pipes, and acquired the

patent.

Piping is not easy because the diameter is larger and thicker

than copper pipes. Even so pipes can be laid along shaped surface. |

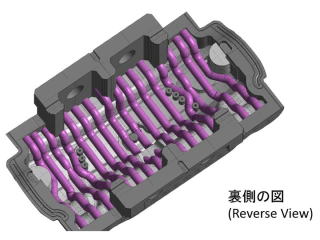

| ■ Mold Design of Cast-in Pipe |

|

|

We arrange with customers about adoption of cast-in pipe technology

or routes of pipes.

We design routes of pipes and examine the layout by 3D CAD. |

|

|

|

| Go back to top of this page |

|

|

| Copyright (C) 1998 Imanishi Manufacturing Co.,Ltd. All Rights Reserved. |

|